S-CMC®

This is a high-performance, low-cost heat dissipation material called Super-CMC, which is completely different from conventional CMC products.

Conventional products are manufactured using a roll forming method, which can result in a wavy, uneven thickness and lack of flatness. In contrast, our hot press diffusion bonding method is an original and superior technique that achieves higher thermal conductivity, lower cost, and stable quality.

Materials and Structures

S-CMC is a clad material made by laminating copper foil and molybdenum foil in multiple layers.

Molybdenum contents in the S-CMC can be lowered to 1/5 to 1/10 than the conventional products.

- The composition of Cu/Mo can be customized according to your specific needs and requirements.

- It is possible to achieve your desired coefficient of thermal expansion.

No adhesive is used in our diffusion bonding method

Structure of S-CMC®

Physical Properties

Performance

Higher thermal conductivity:330 to 360 W/mK (1.5 times higher than the conventional products)

Lower thermal expansion:6 to 10 ppm/K

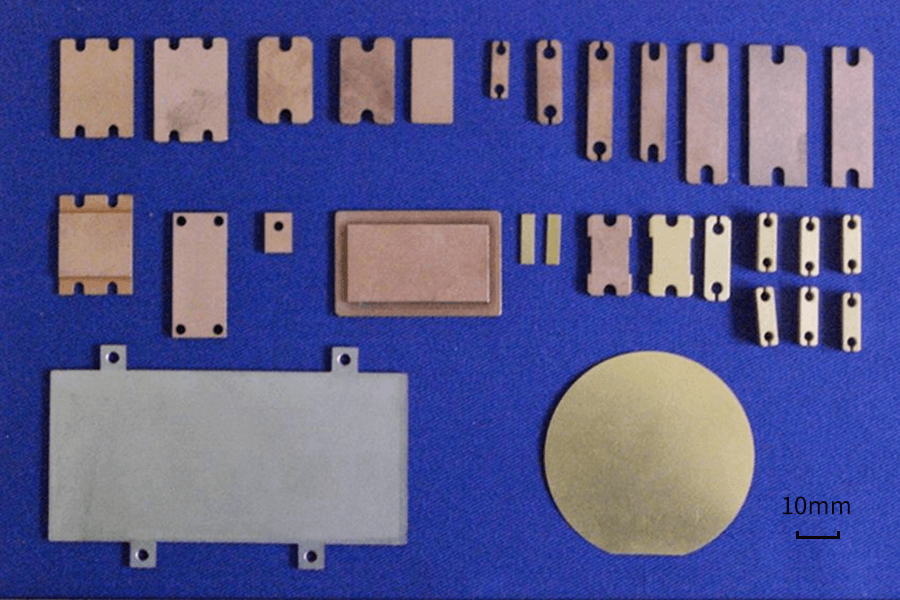

Processed Shape

Based on customer requests, we can manufacture various shapes and thicknesses of products(±7.5μm)

using a wire EDM machine with dimensional tolerances within plus or minus 7.5 μm.

Square corners (R=0) can be shaped.

A wide variety of plating is applicable for this material.

Various shaped and plated products of S-CMC

Cost Performance

-

Low cost

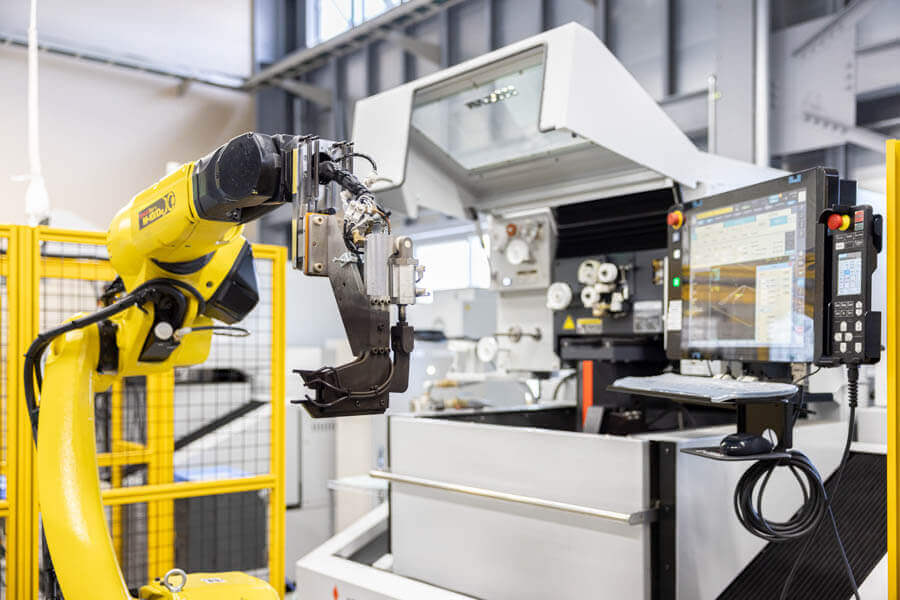

Since ours has a lower Mo content than conventional products, it can contribute to cost reduction for customers. Additionally, we have developed and implemented a massive production system which automates all processes including machining, inspection, and packaging. This allows for efficient and streamlined production. -

Mass production

With our developed massive production system, all processes of machining, inspection, and packaging are automated, ensuring consistent and high-quality products. -

Prototype

We can provide a trial sample of our product at a low cost thanks to our unique production method.

Technology Solutions

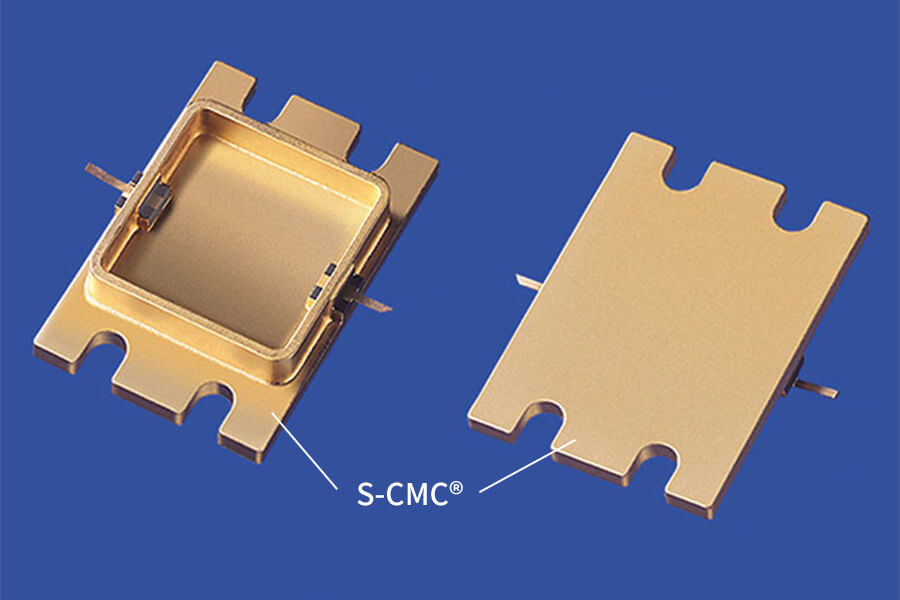

Wireless Communication:Heat Sink for a GAN Chip

Our S-CMC products are used in mobile phone base stations, airplane Wi-Fi systems, and 5G communications. They are ideal for use as heat sinks in semiconductor packages, providing superior heat dissipation and lower thermal expansion even in harsh operating environments

Features of semiconductor packages in which our products are used.

- Protect the IC chip from external environment factors such as water vapor, dust, light, electromagnetic waves, etc.

- Provide mechanical protection to the IC chip

- Insulate the electrical signals input/output from and to the IC chip

- Dissipate the heat generated by the IC chip to the external environment

5G communication equipment and radio base stations

As heat sinks for GAN chips

RF power transistor package

by Kyocera corporation website

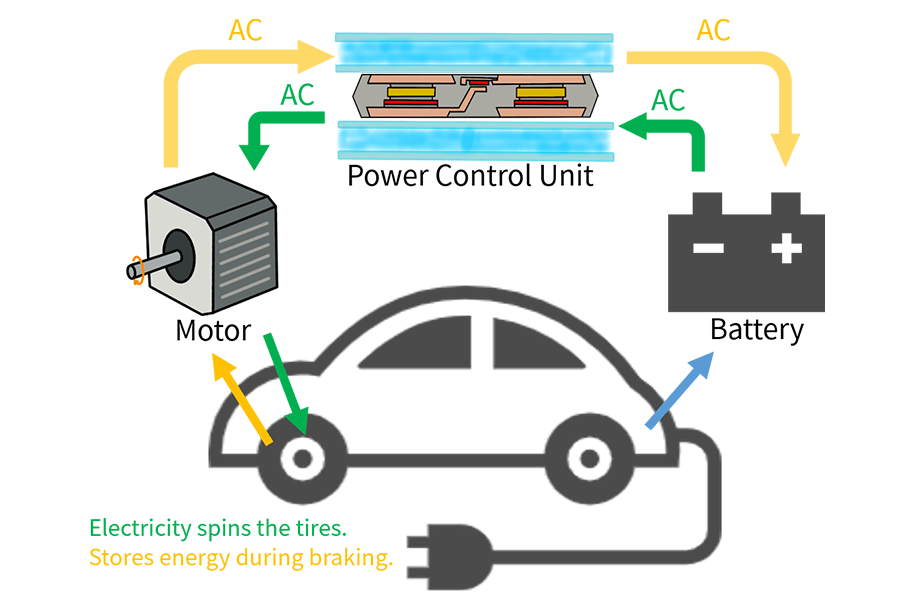

Electric Vehicle Power Control Unit (PCU)

Electric vehicles can efficiently convert DC to AC and AC to DC very frequently.

The control device in electric vehicles, called the electric power control unit (PCU), consists of several power semiconductors that make it highly efficient.

During acceleration, the PCU converts the battery’s electric power from DC to AC and supplies power to a motor, as an AC control system is more advantageous.

During deceleration, it converts electric power from AC to DC to recover regenerated electric power.

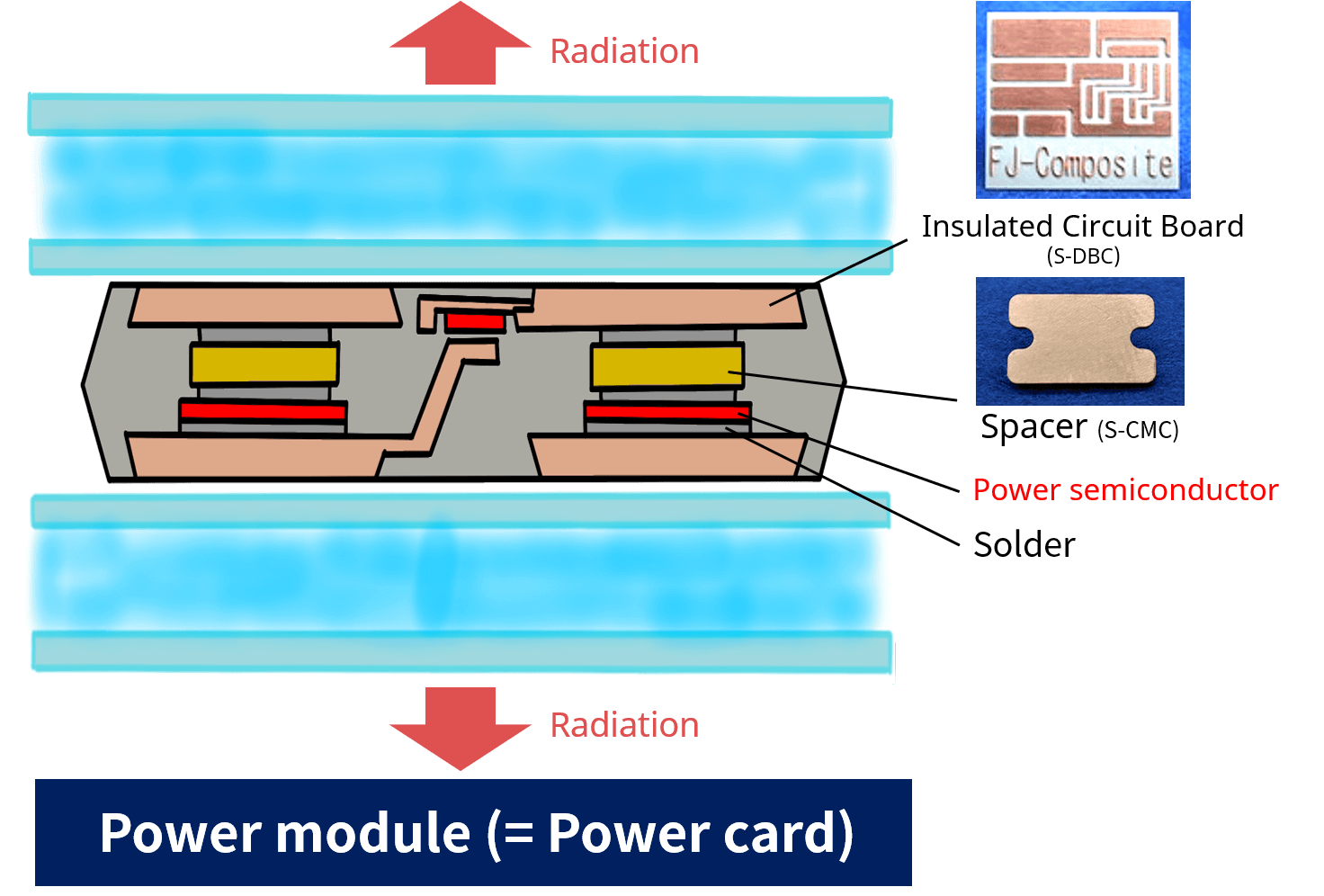

S-CMC® as a spacer (heat dissipation material) for double-sided cooling power devices

A power card, installed in a PCU, can perform high-speed switching on and off to improve energy efficiency.

It is also called a power module in Japan and is installed in a DCS module.

By inserting an S-CMC spacer between a semiconductor chip and a circuit board, stress between the semiconductor chip and bonding interface can be reduced.

The thickness accuracy and heat dissipation efficiency of the spacer in the DSC module are very important.

Electric vehicle power system

During acceleration: the motor runs through the PCU via the battery.

During deceleration: the power generated by the brakes is stored in the battery via the PCU.

Structure of PCU

Patents and Awards

- Patents have been obtained in Japan, the United States, China, and Europe

- Trademarks have been registered in Japan, the United States, and China

-

Received a special award at the 6th Monodzukuri Nippon Grand Award

We received the “Special Award of the 6th Manufacturing Japan Grand Prize” and were commended by the Ministry of Economy, Trade and Industry. This award recognizes outstanding personnel in each generation of those involved in manufacturing, including mid-level personnel who play a core role in manufacturing and production sites, skilled personnel who support traditional and cultural “techniques”, and young personnel who will lead the future of manufacturing.

Publications

- Heat dissipation of LED device by copper-molybdenum composite material

- Development of heat dissipation materials using copper-molybdenum composites

- Development of heat dissipation materials using copper-molybdenum composite materials for 5G