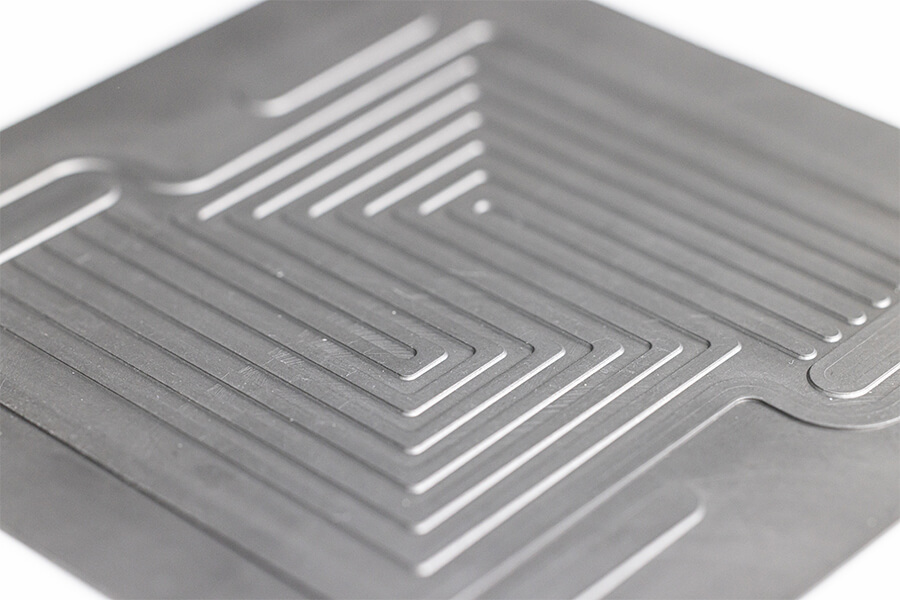

Bipolar Carbon Separator for Fuel Cell

Our bipolar plate is formed with carbon powder and synthetic resin by a mold press forming. We have researched and developed low-cost carbon separators with low electric resistance, high strength, corrosion resistance, high flexibility. Based on the customers’ requests, we can provide fuel cell separators with specifications that can be manufactured using our original method.

Materials and Structures

Carbon powder and synthetic resin

Separators are manufactured using various combinations of thermoplastic and thermosetting resins with carbon.

Please contact first as various requests can be accommodated by us

Physical Properties

Performance

| Bending strength | 50 MPa |

|---|---|

| Electrical resistance | 10 mΩcm |

| Hydrophilic treatment |

Normal pressure, short-time treatment Chemical stability No change in resistance when soaked in 100% methanol Localized hydrophilic treatment is also possible (such as for only flow channels) |

Shape Processing

Free shape processing and thickness adjustment

We manufacture products according to customer needs. Please contact us for more information.

Products manufactured without milling processing

As we use press compression molding with molds, we can even create groove patterns without milling processing.

One of groove patterns of a bipolar carbon separator

Cost Performance

Cost reduction by mold press processing with groove patterns

It can be molded without cutting the plate.

High-speed molding is possible depending on the shape.

Custom products from prototyping to mass production

We can meet your needs for prototype and mass-produced custom products. Based on your requirements for groove patterns, thickness, and our manufacturing methods, we will discuss the feasibility and pricing with you. Please contact us to get started.

Comparison with conventional composite separators

We have already developed a composite separator in which flexible carbon/resin composite sheets are laminated on both sides of a metal foil. With this composite separator, we have confirmed characteristics such as groove processability, ductility (flexibility), conductivity, and corrosion resistance. Fine groove forming and independent forming on both sides are possible by press molding.

Currently, we are developing a separator using carbon powder and resin for high-speed press molding. This new separator can be produced at a lower cost due to its materials and productivity, and it also has excellent corrosion resistance because it is made of carbon.

Technology Solutions

For fuel cell vehicles

A fuel cell vehicle can provide a longer driving range than a battery electric vehicle. For this reason, fuel cells are commonly used in larger vehicles such as buses and trucks.

Buses and trucks typically follow pre-determined routes and return to designated locations at the end of the day, which makes it more efficient to have a limited number of hydrogen stations available. As each fuel cell vehicle requires 800 separators, we are conducting research and development into manufacturing methods suitable for mass production.

Structure of PEFC (Polymer Electrolyte Fuel Cell)

Separator plate is one of the main three components that make up the PEFC.

For stationary power supply

A fuel cell is a device that generates electricity with hydrogen and oxygen through a chemical reaction, without producing carbon dioxide emissions. Because it can convert chemical energy directly into electrical energy, it is an eco-friendly and highly efficient technology.

Awards

-

Nominated for the successful commercialization of the Supporting Industry Initiative

Supporting Industry refers to advanced new industrial fields that are indispensable for the competitiveness of industries that will drive the Japanese economy now and in the future. It also refers to the high-performance materials and basic industries.

In the first year (FY 2006), we developed a separator plate for a fuel cell (PEFC) and were recognized as a successful company by the Small and Medium Enterprise Agency. - Environmental energy

Publications

- Carbon Molded Separator Plate for Polymer Electrolyte Fuel Cell

- Manufacturing method of carbon/resin mold separator and an effect of resin ratio on its properties

- Low-cost manufacturing technology for PEFC separator plates